Technical: Forging Copper Blank + Precision Machining

Product Name : Copper Parts

Main Use : For Industrial Machinery Parts , Pipeline , Marine Hardware , Auto Parts , Set lights

Technical Parameter

Technical: | Forging Copper Blank+Precision Machining |

Material: | CuZn40PB2(MS58)) |

Material Standrad: | GB,ASTM,AISI,DIN,BS,JIS,NF |

Blank Weight: | 0.05kg~5kg |

Forging Dimension Tolerance: | CT10Grade |

Forging Surface Roughness: | Ra6.4 – 3.4 |

| Rough of Machining Surface: | Ra0.8-1.6 |

Support File of Format: | ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png |

Machining Equipment | 30CNC Turning Machine, Drilling Machine |

Surface Finished | Chromium Plating , Nickel Plating , Polishing , Silver Plating , Gold Plating |

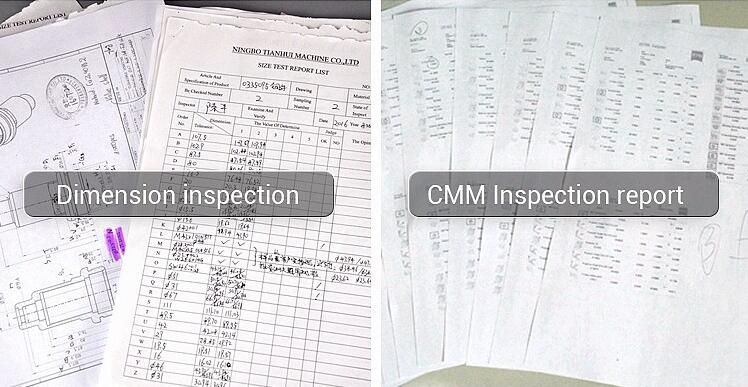

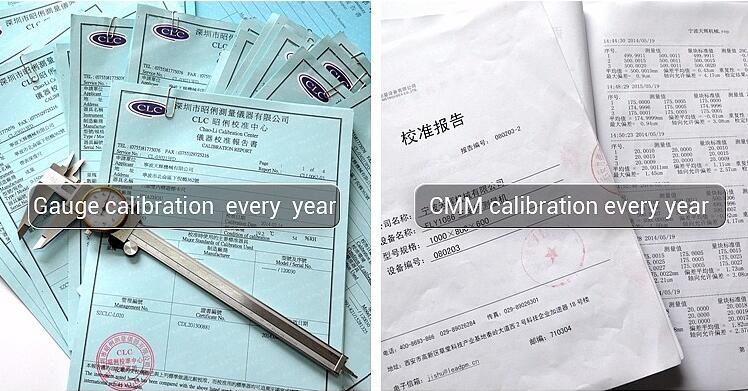

Meaure Tools : | Three Coordinate, Micrometer, Caliper, Height Gauge,Screw Gauge,Pin Guage |

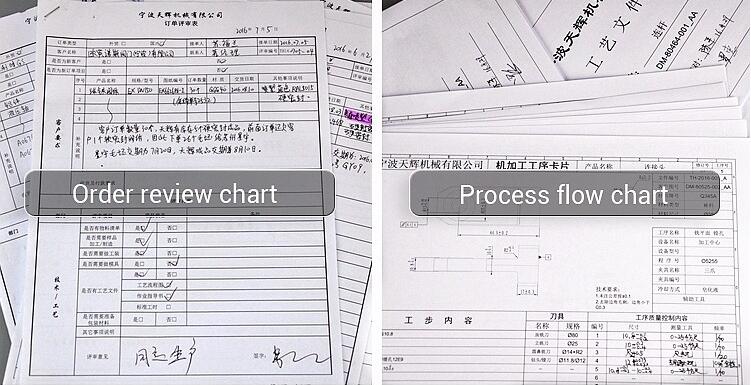

Inspection: | First Checking , Checking , Final Checking |

| QC Reports | CuZn40Pb2 Material Report,Product Dimension Inspection Report |

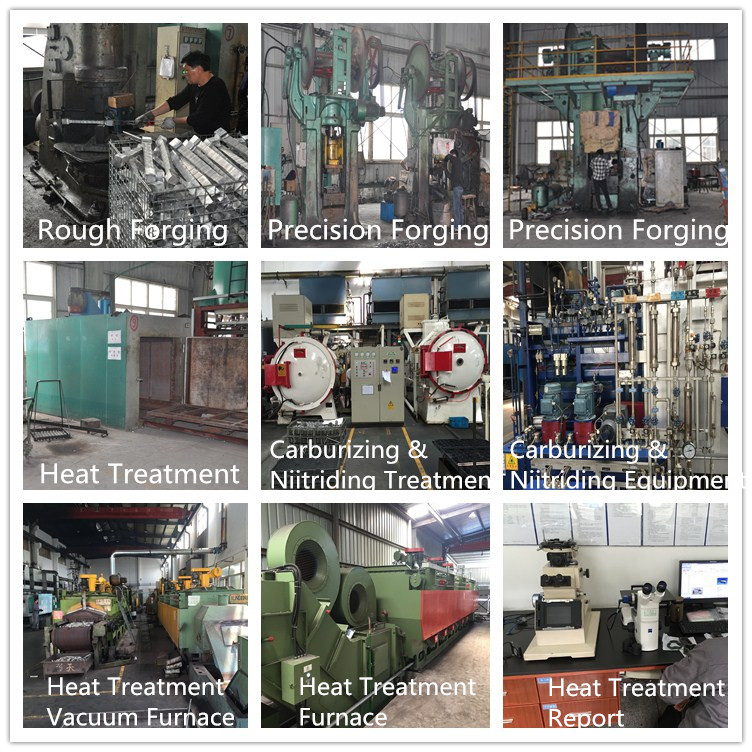

Technical Process

1.Manufacture mould of Hot Forging Copper Part

2.Forging Copper Blank

3.Precision Machining Copper Part(Turing Machine)

Machining Capability Inspection Capability

We have produced more than 700 different types of machining product , these product are mainly exported to Europe, the United States and Japan, our engineers and workers are familiar with the overseas customer engineer standards and quality requirements. As far as now my company has 18 sets of machining center, 3 sets of inclined bed, 21 CNC machine tools, 1 sets of CMM inspection center, 3 sets of manual lathes, milling machines 2, 18 Taiwan 1 Taiwan drilling machine, ultrasonic cleaning machine, 1 sets of vibration grinding machine, 1 sets of welding machine.

Tianhui Factory

Tianhui CNC's Shop

Tianhui CNC Center's Shop

Copper Parts Hot Forging Capability

As a professional Copper Hot Forging Factory , only manufacture high quality carbon hot forging parts . Edges clearly , Stable size of hot forging parts (Critical Sizes can be up to CT5 -CT6 Grade ), Smooth Suface ( Roughness of Casting Surface Ra6 ) . Reshaping hot forging parts by Press Maching , Fixture Tool and Measure rectification .

Quality Control

Magnetic particle testing

Production Processes & QC Reports

ISO9001:2015 Certificate of Quality Management System

Safty Packing

>