Stainless steel casting is not only suitable for a variety of types, all kinds of alloy casting, and the production of casting dimensional accuracy, surface quality is higher than other casting methods, and even other casting methods are difficult to cast complex, high temperature resistance, not easy to process the casting, can be used investment precision casting.

So-called investment casting process, simply be with fusible materials (such as wax material or plastic) made meltability model (referred to as "investment pattern or model), on which the coated with several layers of tailor-made refractory coating, after drying and hardening type to form a whole shell, reoccupy steam or hot water from the melt in the shell model, and then put type shells in the sand, dry sand by filling in all round its modelling, Finally, the casting shape is put into the roaster and roasted at high temperature (if high strength shell is used, the demelled shell can be directly roasted without molding). After roasting, molten metal is poured into the casting shape or shell to get the casting.

The dimensional accuracy of investment castings is high, generally up to CT4-6(CT10-13 for sand casting and CT5-7 for die casting). Of course, due to the complex technological process of investment casting, there are many factors that affect the dimensional accuracy of castings. Such as shrinkage, deformation of investment casting mould materials, shell in the process of heating and cooling line quantity change, alloy of shrinkage and deformation of the casting during solidification, etc., so ordinary size although higher precision investment castings, but still need to improve the consistency (in medium and high temperature of the wax casting size consistency to improve a lot).

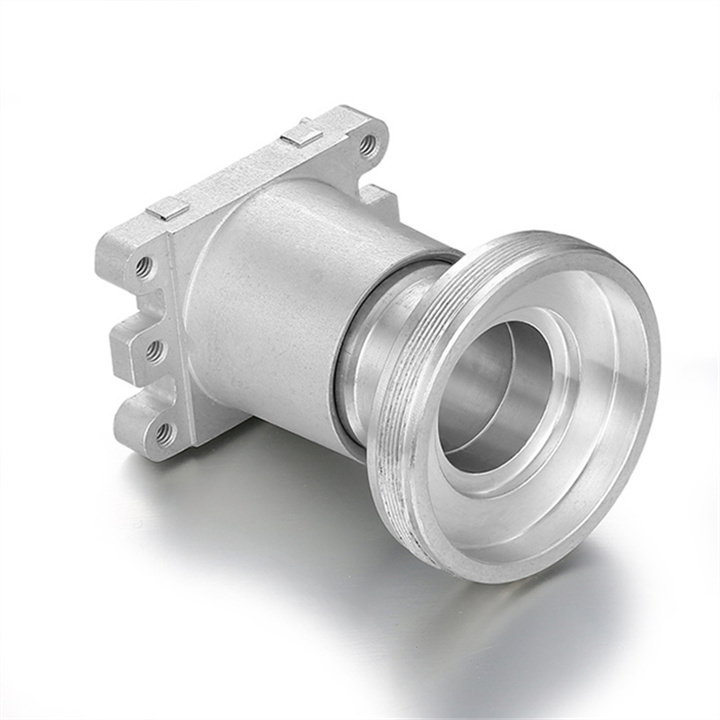

When pressing the investment mold, the pressure mold with high surface finish of the cavity is used, so the surface finish of the investment mold is also relatively high. In addition, the shell is made of high temperature resistant special binder and refractory material made up of refractory coating coated on the investment mold, and the surface of the cavity in direct contact with the molten metal has high finish. Therefore, the surface finish of investment castings is higher than that of general castings, generally up to Ra.1.6~3.2μm.

The biggest advantage of investment casting is that because of the high dimensional accuracy and surface finish of investment casting, it can reduce the mechanical processing work. Only a little processing allowance can be left for the parts with high requirements. Even some castings can only be left for polishing and polishing, so they can be used without mechanical processing. It can be seen that the use of investment casting method can greatly save machine tools and equipment and processing hours, and greatly save metal raw materials.

Another advantage of the investment casting method is that it can cast complex castings of various alloys, especially superalloy castings. For example, the blade of a jet engine, its streamlined profile and cooling cavity can hardly be formed by machining technology. Using investment casting technology can not only achieve mass production, ensure the consistency of casting, but also avoid the stress concentration of residual cutting lines after machining

Copyright © Tianhui Machinery Co.,Ltd All Rights Reserved Website Map XML