Ningbo Tianhui Machine Co., Ltd. has advanced processing equipment, rich experience in the production of skilled workers , and advanced 3 coordinate testing equipment, good at processing stainless steel precision castings. Stainless steel precision casting ,also named investment casting, belongs silicon sol process. It is an excellent casting technology with few cutting or no cutting in the casting industry, so its application is very extensive, not only applicable to various types, but also suit to all kinds of alloy. And the accuracy and surface of castings are better than other casting methods . Even other casting method is difficult to cast the complex, high temperature and easy machining castings, all can be used in precision casting cast.

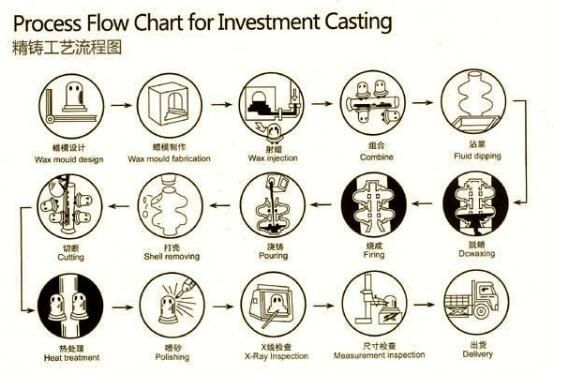

The so-called investment casting process, simply using fusible materials (such as wax or plastic) made of fusible model (referred to as mold or model), in some special refractory coating layer on the coating, after drying and hardening to form a whole shell, and then steam or hot water from the shell in the melt the shell model, and then placed in a sand box, dry sand mould filling in the round, the casting into the baking furnace after high temperature calcination (such as the use of high strength shell, no need profiling and directly be baking shell after ejection), after mould or shell by roasting, can get the casting from the pouring molten metal .

Casting with precision size , generally up to CT4-6 (CT10~13 for sand casting, die casting, CT5~7) . But as the investment casting process is complex, there are many factors that affect the dimensional accuracy of castings, such as mold material, mold shrinkage deformation, shell during heating and cooling line changes, alloy the shrinkage and deformation of casting during solidification process, so the size precision castings although higher, but the consistency still need to improve (by casting size consistency, high temperature wax to improve a lot).

When the mold is pressed, the surface of the mold cavity is of high degree of finish, so the surface of the melt is relatively high. In addition, the shell is made of a refractory coating which is prepared by the high temperature resistant special binder and refractory coating and is made of a refractory coating which is directly contacted with the molten metal. So, the surface finish of the investment casting is higher than that of the common casting parts, generally up to Ra.1.6~3.2 mu m.

The investment casting the biggest advantage is due to the investment casting with high dimensional accuracy and surface finish, so can reduce machining work, only in parts of the parts of the high demand for a little machining allowance , even some casting only keep grinding and polishing allowance, not mechanical processing , can use directly. It can be seen that the use of investment casting method can save a lot of machine tools and processing time, greatly saving the metal raw materials.

Another advantage of the investment casting method is that it can cast a variety of alloys of the complex castings, in particular, can cast high temperature alloy castings. Such as jet engine blades, the streamlined profile and cooling with inner chamber, with the machining process can hardly formation. The production of the investment casting process can not only be used in batch production, but also can ensure the consistency of the casting, and avoid the stress concentration of the residual knife pattern after machining.

So it is widely used in aviation, automobile, machine tool, ship, internal combustion engine, gas turbine, telecommunication equipment, weapons, medical equipment and tools, and also used in the manufacture of Arts and crafts.

Copyright © Tianhui Machinery Co.,Ltd All Rights Reserved Website Map XML